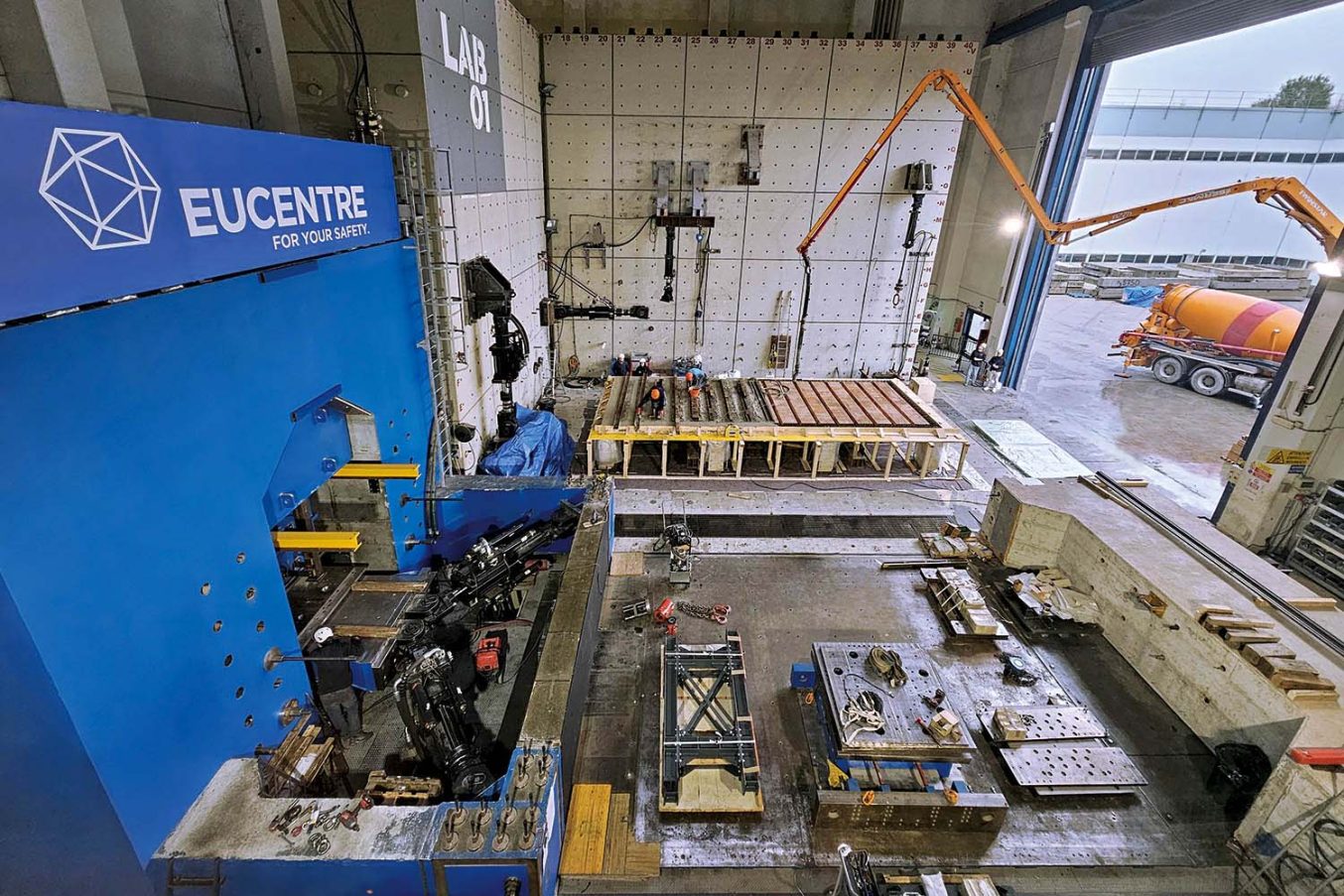

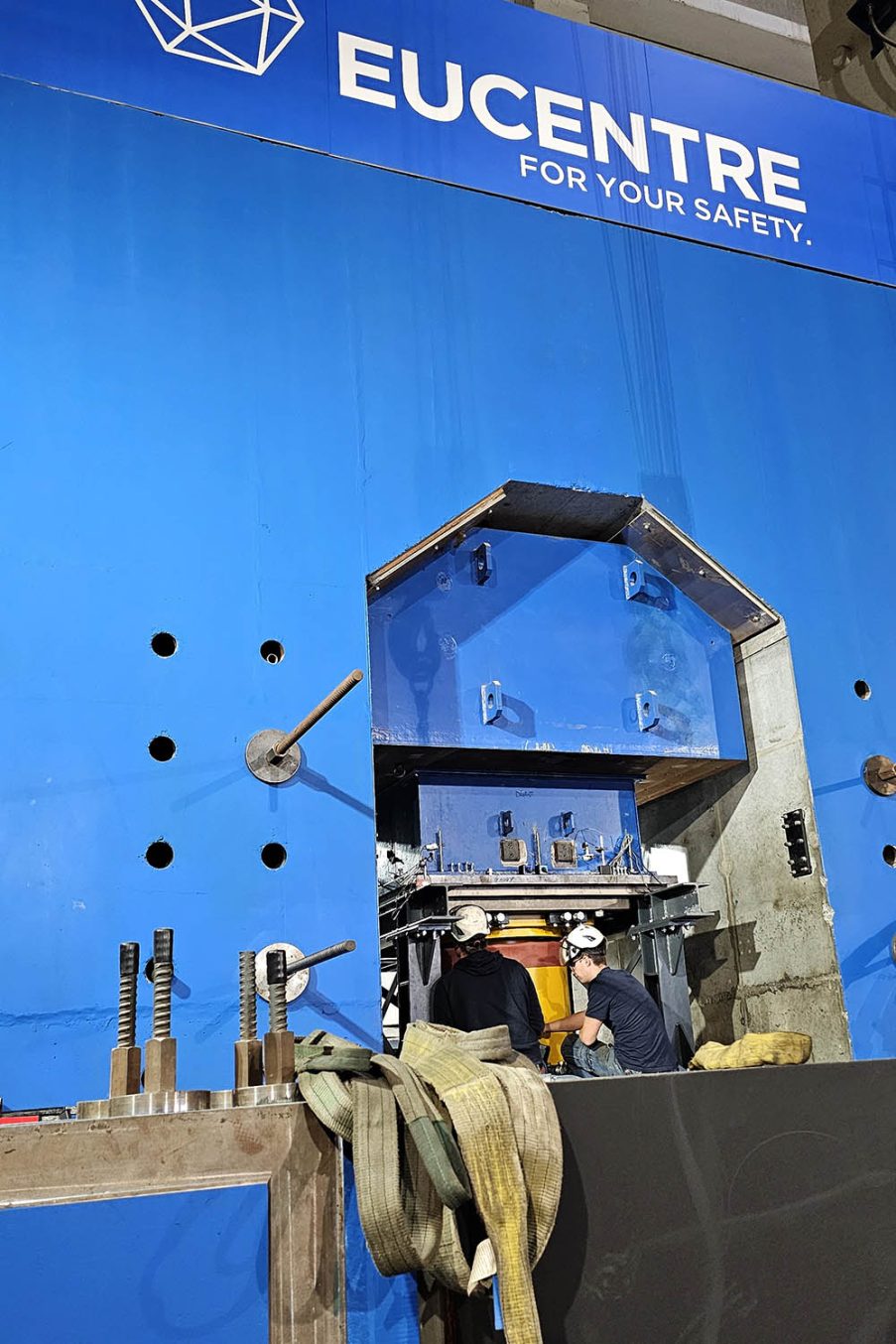

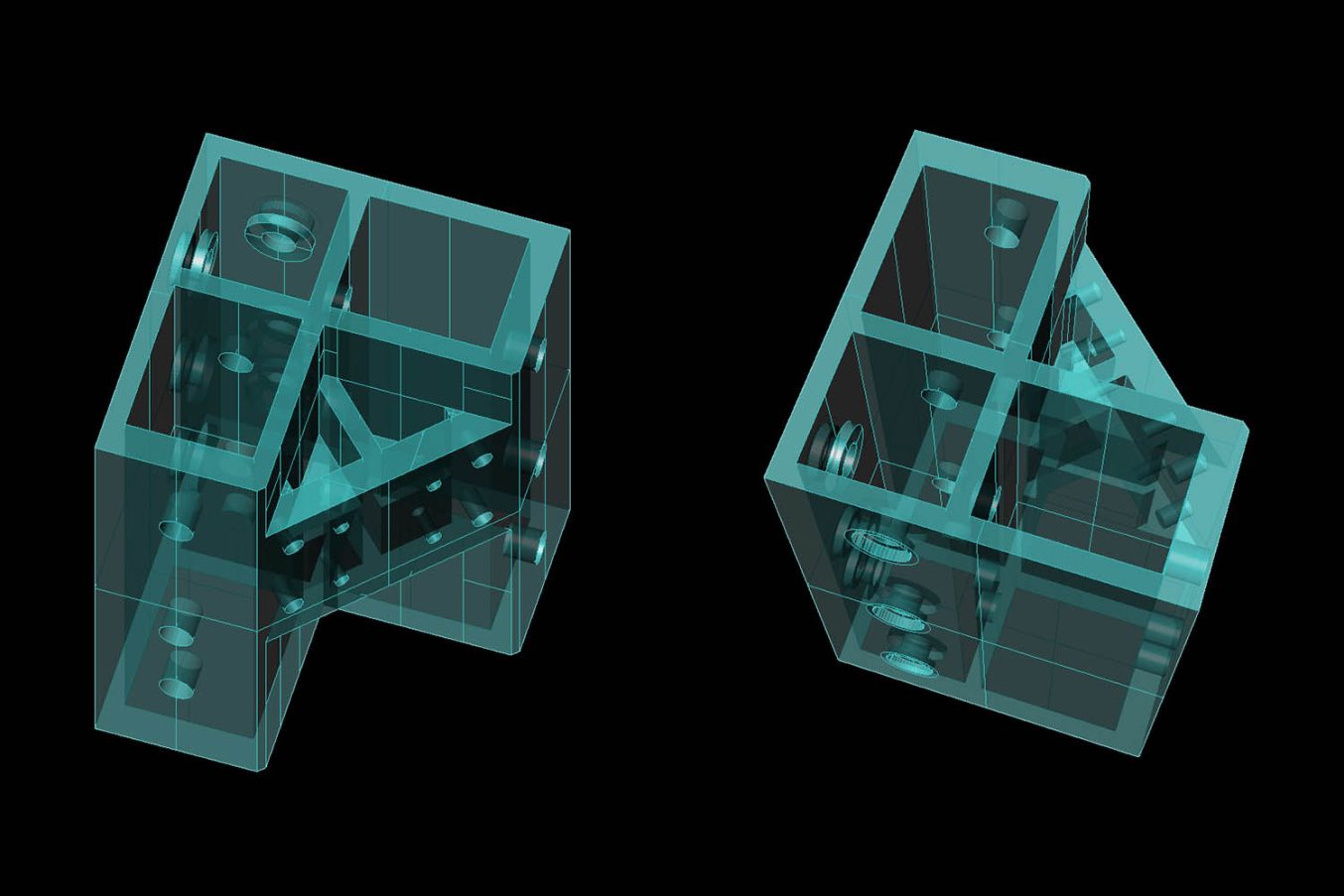

The BTS (Bearing Test System) is an advanced experimental device designed to test the performance of seismic isolation and dissipation devices, such as rubber isolators, structural bearings, and metal or viscous dissipators, in a laboratory setting. The system can reproduce the stresses that these elements experience during an earthquake in a controlled manner by applying horizontal and vertical loads statically, cyclically or dynamically.

Thanks to its high-performance structure and ability to generate multi-axial movements, the BTS can assess the mechanical behaviour and durability of these devices with great precision by simulating extreme real-world conditions. It is a vital tool for qualifying products intended for the seismic protection of buildings, bridges and strategic infrastructure. Data collected during testing not only ensures compliance with regulations, but also improves the design and reliability of insulation systems, supporting scientific research and technological innovation in the field of seismic safety.

The BTS is accredited to certain standards, attesting to the quality of testing carried out by the centre. These accreditations ensure that the products tested not only meet the technical requirements, but can also be used with maximum reliability in strategic or highly seismically vulnerable works. Data collected during testing also contributes to scientific research and the continuous improvement of seismic protection technologies, providing valuable support to the fields of engineering and structural safety.

Eucentre is a non-profit private law foundation whose mission is to conduct research and provide training and services in earthquake and safety engineering

Eucentre is a non-profit private law foundation whose mission is to conduct research and provide training and services in earthquake and safety engineering  Eucentre promotes science, research and innovation for the benefit of the community, offering targeted methodologies and concrete solutions for prevention, safety and resilience. It collaborates with institutions and companies to disseminate competencies for the common good.

Eucentre promotes science, research and innovation for the benefit of the community, offering targeted methodologies and concrete solutions for prevention, safety and resilience. It collaborates with institutions and companies to disseminate competencies for the common good. Eucentre conducts earthquake engineering research and risk reduction studies via laboratory testing and numerical analysis to enhance seismic performance and develop innovative solutions

Eucentre conducts earthquake engineering research and risk reduction studies via laboratory testing and numerical analysis to enhance seismic performance and develop innovative solutions  Eucentre carries out research activities in earthquake engineering and risk reduction through laboratory testing and numerical analysis, aiming to improve the seismic performance of structures and soils and to develop innovative seismic retrofitting techniques.

Eucentre carries out research activities in earthquake engineering and risk reduction through laboratory testing and numerical analysis, aiming to improve the seismic performance of structures and soils and to develop innovative seismic retrofitting techniques. The Foundation promotes diverse and high-quality training activities aimed at academic and professional contexts, with constantly updated and innovative programs and initiatives designed to meet the evolving needs of the sector and society

The Foundation promotes diverse and high-quality training activities aimed at academic and professional contexts, with constantly updated and innovative programs and initiatives designed to meet the evolving needs of the sector and society  Eucentre ensures communication aimed at informing institutions, professionals, and citizens about ongoing activities and projects, with the goal of disseminating useful and accessible content and knowledge. It contributes to promoting a shared and informed culture of prevention and resilience.

Eucentre ensures communication aimed at informing institutions, professionals, and citizens about ongoing activities and projects, with the goal of disseminating useful and accessible content and knowledge. It contributes to promoting a shared and informed culture of prevention and resilience.